Introduction: The Critical Need for Dairy Preservation

Dairy products—from fresh milk and aged cheese to probiotic yogurt and heavy cream—are nutritional powerhouses, but their rich composition (proteins, fats, lactose) makes them a prime target for spoilage. Globally, an estimated 1/3 of dairy is wasted annually due to microbial growth and improper preservation, not only hitting manufacturers’ bottom lines but also posing food safety risks for consumers. For brands and producers, effective preservation isn’t just about extending shelf life—it’s about delivering on trust.

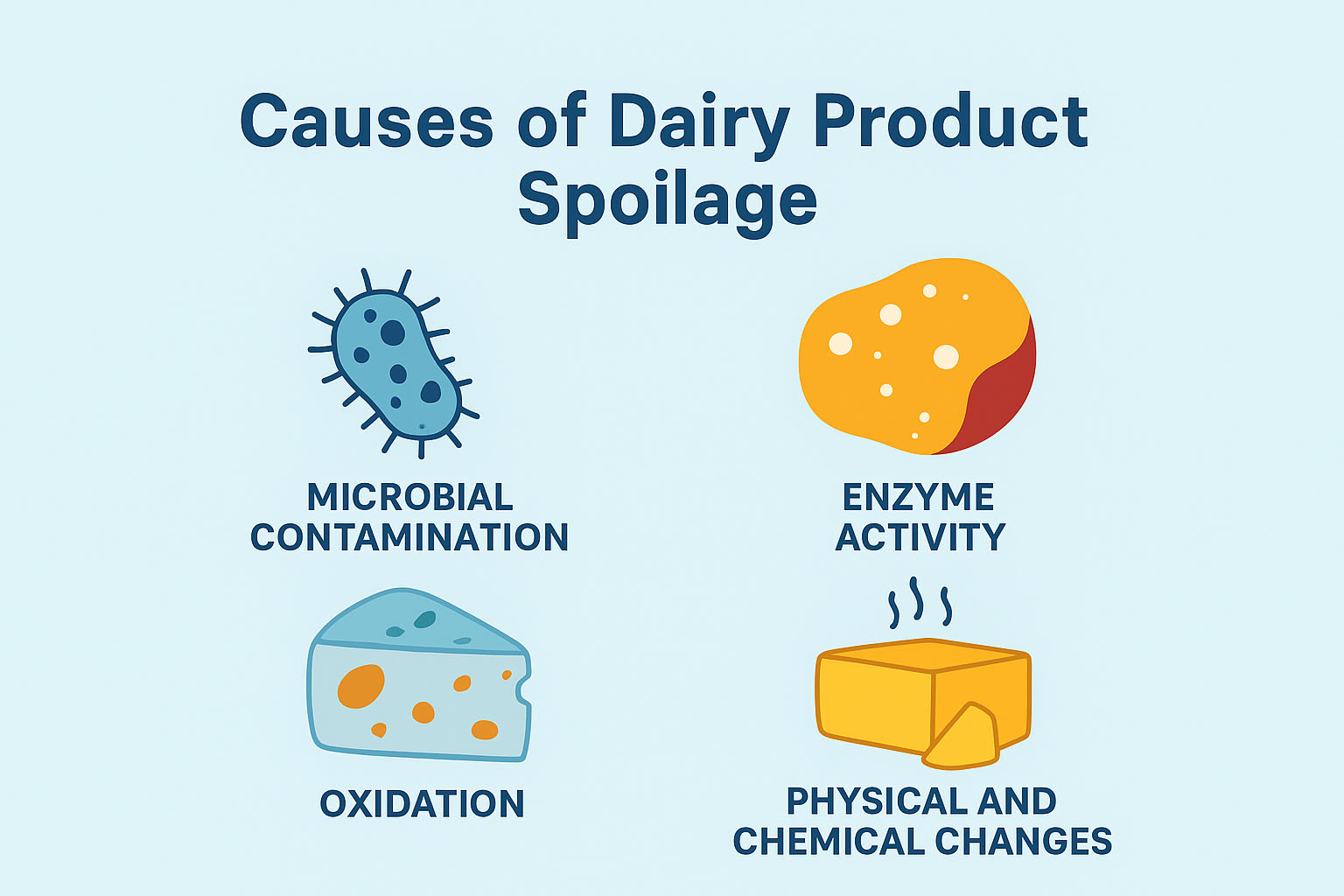

Why Dairy Spoils So Easily

Dairy’s vulnerability to spoilage stems from three key factors, which often work together to accelerate decay:

1. Nutrient density: Proteins and lactose provide ideal “food” for bacteria and molds.

2. Moisture content: Most dairy products have a water activity (aw) above 0.9, a level that supports rapid microbial reproduction.

3. Neutral pH: Fresh milk has a pH of 6.5–6.7 (near neutral), unlike acidic foods (e.g., citrus) that naturally inhibit microbes.

4. Temperature sensitivity: Even small fluctuations—like a 2℃ rise above standard refrigeration (4℃)—can double the growth rate of spoilage bacteria like *Pseudomonas*.

Common Spoilage Issues Consumers & Producers Face

- Sour milk: Caused by lactic acid bacteria (LAB) overgrowth, which breaks down lactose into lactic acid.

- Moldy cheese: Visible fuzzy growth (often *Penicillium*) on surfaces, even in refrigerated conditions.

- Bloated yogurt: Gas produced by spoilage bacteria (e.g., *Enterobacter*) that ferments lactose, leading to bulging containers.

- Rancid butter: Oxidation of milk fats, resulting in a bitter, “off” taste—common in butter stored above 10℃.

Microorganisms That Threaten Dairy Safety

Not all microbes in dairy are harmful (e.g., LAB used in yogurt fermentation), but certain species can ruin products or cause illness. Here are the most concerning:

- Lactic Acid Bacteria (LAB): Beneficial in controlled fermentation (e.g., making yogurt), but excess growth causes souring in milk or cheese.

- Pseudomonas spp.: A major culprit in refrigerated dairy—*Pseudomonas fluorescens* produces enzymes that break down milk proteins, leading to a “ropy” texture and off-flavors.

- Molds (Penicillium, Aspergillus): Some strains (e.g., Aspergillus flavus) produce mycotoxins, which remain harmful even after mold is removed from cheese.

- Pathogens: Listeria monocytogenes is particularly dangerous— it survives in refrigeration, contaminates soft cheeses (e.g., brie), and can cause severe illness in pregnant people and the elderly. Salmonella and E. coli are also occasional risks in raw or underprocessed dairy.

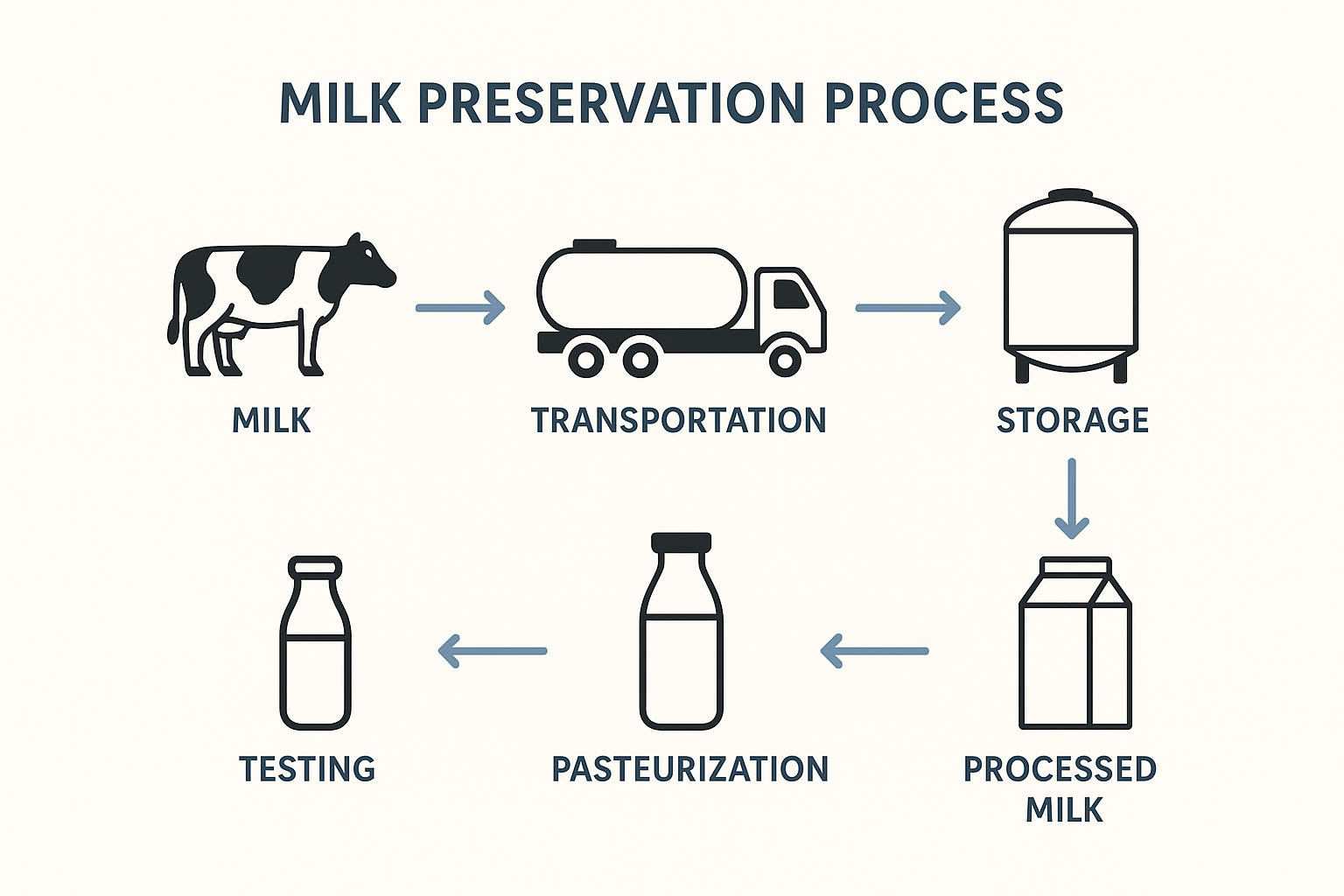

Traditional Dairy Preservation Methods

For decades, producers have relied on these tried-and-true techniques to slow spoilage:

- Refrigeration: The most common method—storing dairy at 0–4℃ slows microbial growth, but doesn’t stop it (e.g., *Listeria* still multiplies, just more slowly).

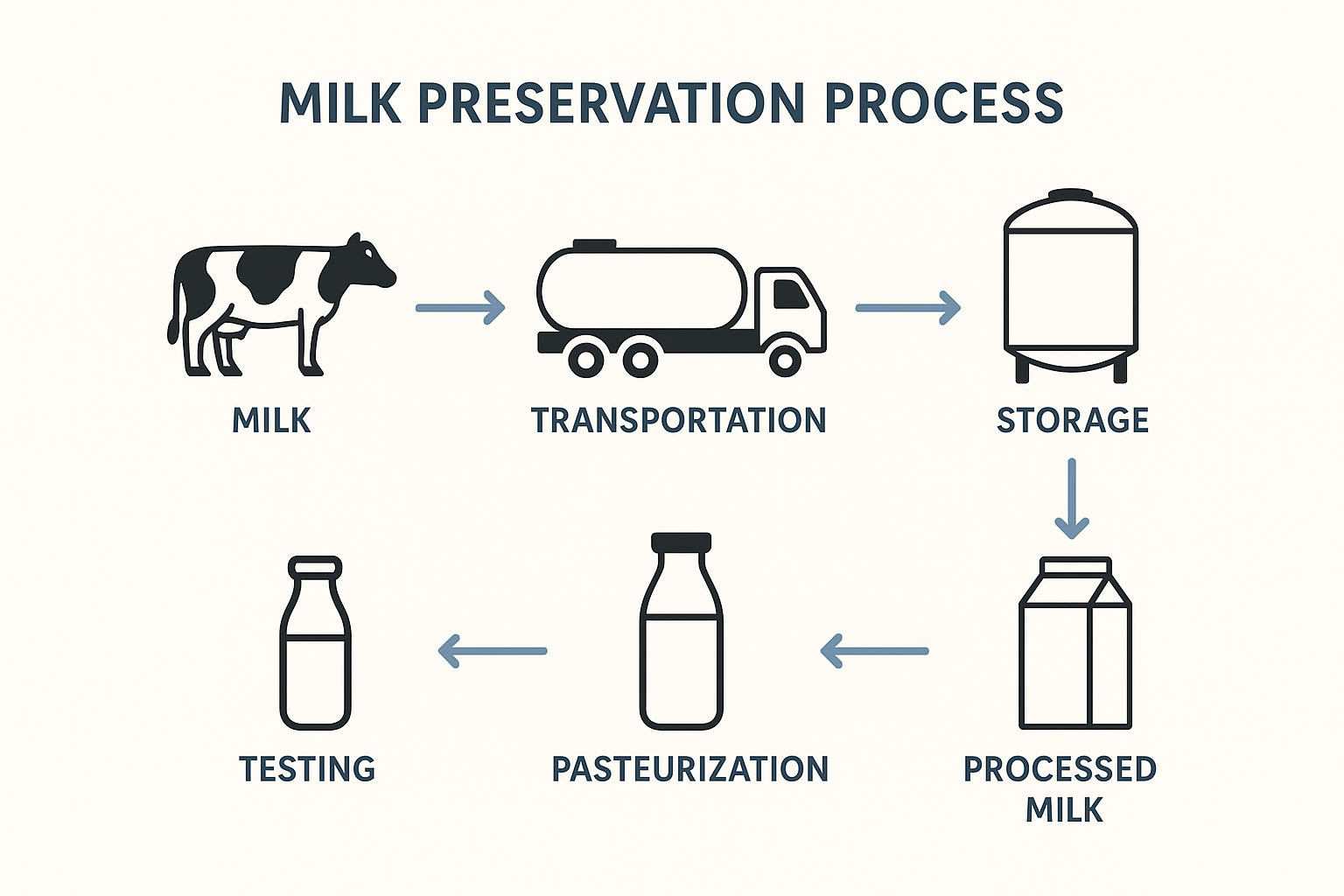

- Heat treatment:

- Pasteurization (60–75℃ for 15–30 seconds): Kills most pathogens and spoilage bacteria, extending milk’s shelf life to 2–3 weeks (refrigerated).

- UHT (Ultra-High Temperature, 135–150℃ for 2–5 seconds): Destroys nearly all microbes, allowing milk to be stored at room temperature (unopened) for 6+ months.

- Fermentation: Adding beneficial LAB (e.g., *Lactobacillus*) lowers dairy’s pH to 4.0–4.5, creating an acidic environment that inhibits harmful microbes—key for yogurt, kefir, and sour cream.

- Packaging: Modified Atmosphere Packaging (MAP, using CO₂ or N₂) reduces oxygen, slowing mold growth and oxidation; vacuum packaging is ideal for hard cheeses, preventing surface mold.

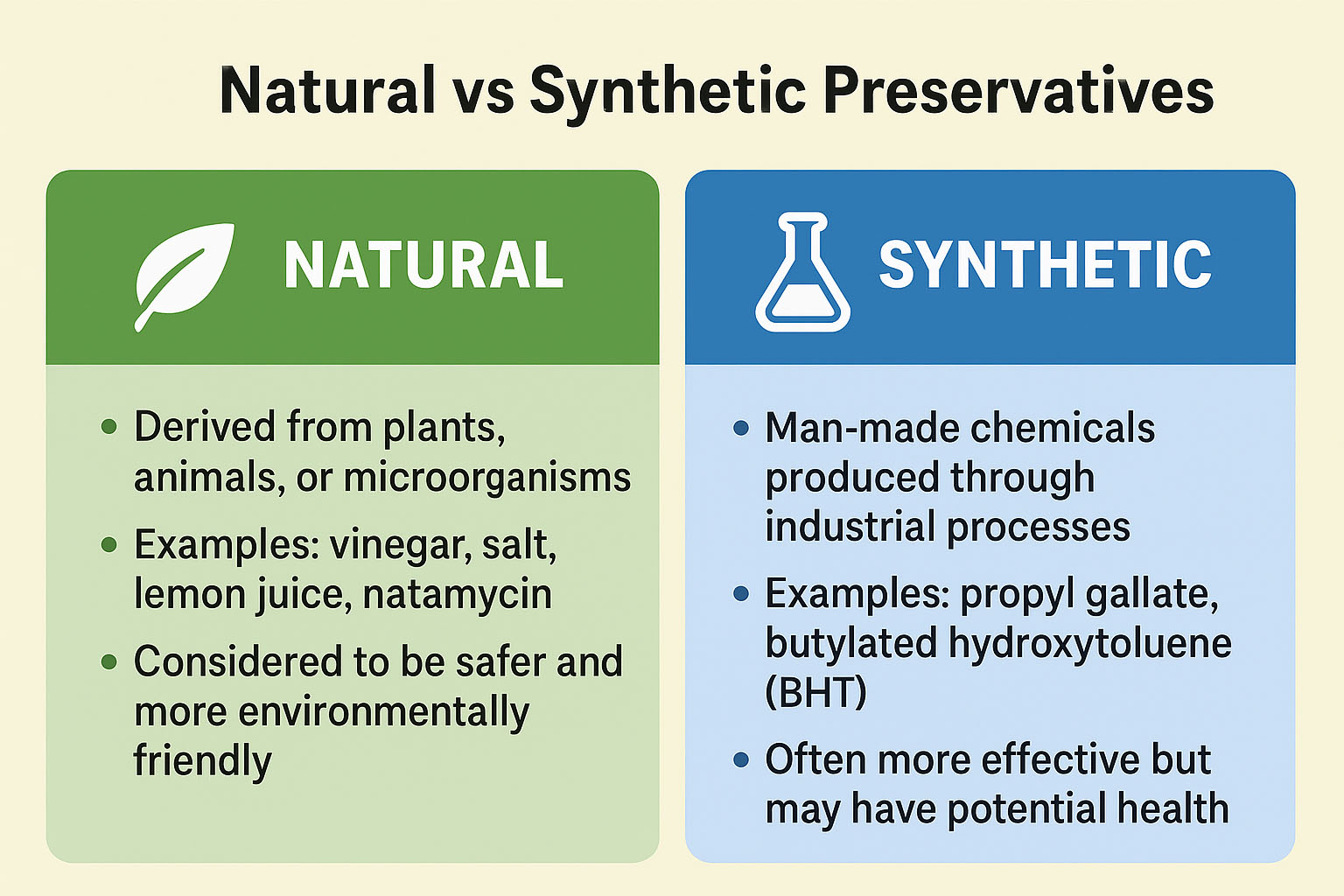

Natural Preservatives: Safe, Effective Alternatives

As consumers demand “clean label” products (free from synthetic additives like sodium benzoate), natural preservatives have become a game-changer for dairy. Here are the most widely used and trusted options:

1. Nisin A peptide produced by Lactococcus lactis (a harmless LAB), nisin targets gram-positive bacteria—including Listeria and spoilage-causing LAB. It’s especially effective in cheese (e.g., cheddar, mozzarella) and processed dairy (e.g., cream cheese), where it’s added at 0.02–0.05g/kg. Studies show nisin can extend cheese shelf life by 2–3 times while maintaining flavor.

2. Natamycin Derived from the bacterium Streptomyces natalensis, natamycin is a mold and yeast inhibitor. Unlike other preservatives, it’s often applied as a surface coating (e.g., on brie, Camembert, or sliced cheese) to prevent fuzzy mold growth. It’s safe for consumption (human bodies don’t absorb it) and approved by regulatory bodies worldwide, including the FDA and EU.

3. ε-Polylysine (ε-PL) A naturally occurring polymer made by Streptomyces albulus, ε-PL has broad-spectrum activity against both gram-positive and gram-negative bacteria, as well as molds. It’s ideal for dairy beverages (e.g., flavored milk, smoothies) and desserts (e.g., pudding), where it dissolves easily and doesn’t alter taste or texture. In 2024, the EU updated its regulations to classify ε-PL as a “clean label” preservative, boosting its use in European dairy products.

The Future of Dairy Preservation

The next era of dairy preservation will focus on synergy—combining traditional methods with natural preservatives to maximize safety and sustainability. Key trends include:

Preservative blends: Mixing nisin and ε-PL to cover a wider range of microbes (e.g., in plant-based dairy alternatives, which face similar spoilage issues).

Smart packaging: Packaging embedded with natural preservatives (e.g., natamycin-coated films) that release slowly, extending shelf life without direct additive use.

Consumer-centric innovation: Brands are highlighting “no synthetic preservatives” on labels—sales of such dairy products grew 18% globally between 2022–2024, per industry reports.

Conclusion: Building a Safer, Fresher Dairy Future

Dairy preservation is no longer just about “stopping spoilage”—it’s about balancing safety, sustainability, and consumer trust. By leveraging natural preservatives like nisin and natamycin, producers can meet the demand for clean-label products while cutting waste and protecting public health. As technology advances, the combination of natural solutions and smart practices will ensure that dairy remains a safe, nutritious staple for years to come.